| s/y Nine of Cups Repainting/Refurbishing the Mast Opua, NZ 2010 |

| Painting the Mast ... this year's big project |

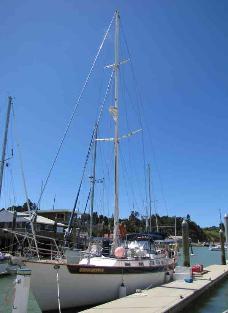

One particularly large project we've put off

for several years now is pulling the mast. It

needed stripping, repainting and rewiring.

We figured now was as good a time as any

and after this past winter, sooner was better

than later. We solicited several quotes from

several different parts of New Zealand, but

the quotes we got from the Opua tradesmen

were the best, so here we stayed. David

prepped the mast by removing all running

rigging and removing cotter pins and

loosening turnbuckles from shrouds and

stays. He stripped the boom of its hardware

and we carried it to the boatyard. All wiring

which runs through the mast

(radar/lights/etc)was disconnected. We

were getting serious. We headed to the

slipwell where a huge crane was waiting

along with the rigger and his crew.

for several years now is pulling the mast. It

needed stripping, repainting and rewiring.

We figured now was as good a time as any

and after this past winter, sooner was better

than later. We solicited several quotes from

several different parts of New Zealand, but

the quotes we got from the Opua tradesmen

were the best, so here we stayed. David

prepped the mast by removing all running

rigging and removing cotter pins and

loosening turnbuckles from shrouds and

stays. He stripped the boom of its hardware

and we carried it to the boatyard. All wiring

which runs through the mast

(radar/lights/etc)was disconnected. We

were getting serious. We headed to the

slipwell where a huge crane was waiting

along with the rigger and his crew.

A rigger adjusts the crane sling on the

mast for hoisting.

mast for hoisting.

David helps the rigger get the mast

loose below deck as the crane starts

hoisting.

loose below deck as the crane starts

hoisting.

Slowly, but surely, the mast came up,

up, up...unstepped after having been

seated in place for nearly 25 years.

up, up...unstepped after having been

seated in place for nearly 25 years.

Once off the boat, the crane moved the

mast to the able hands of the waiting crew.

mast to the able hands of the waiting crew.

Special trolleys specifically designed to

hold a mast, allowed the crew to move

it easily across the boatyard to its

temporary resting place for stripping of

hardware and preparation for painting.

hold a mast, allowed the crew to move

it easily across the boatyard to its

temporary resting place for stripping of

hardware and preparation for painting.

Removing all the hardware from the mast and

then stripping the paint was quite a chore. We

took photographs of all hardware in place

before we removed it in hopes that we'll figure

out where everything goes when it's time to

reassemble it all. David's most useful tool during

the process? An impact driver and a very big

hammer. He went through lots of bits!

then stripping the paint was quite a chore. We

took photographs of all hardware in place

before we removed it in hopes that we'll figure

out where everything goes when it's time to

reassemble it all. David's most useful tool during

the process? An impact driver and a very big

hammer. He went through lots of bits!

The 63' mast looks about 200' long

when you're getting ready to strip the

paint off it.

when you're getting ready to strip the

paint off it.

It's a big, big project and it's almost

done..just a bit more to do. More photos

and explanatory text update to follow.

Check back soon.

done..just a bit more to do. More photos

and explanatory text update to follow.

Check back soon.

Once the sanding was finally complete, the

mast got a good hosing down with fresh

water to clean off all the loose dust and

paint particles.

mast got a good hosing down with fresh

water to clean off all the loose dust and

paint particles.

Very soon after stripping, David applied an

acid etching wash which removes all the

surface corrosion. Since the mast is so long

and time is critical, he did it in sections.

acid etching wash which removes all the

surface corrosion. Since the mast is so long

and time is critical, he did it in sections.

The acid wash must be rinsed off. Within 60

minutes, Aludine, a yellowish liquid, must be

applied which temporarily seals the surface.

minutes, Aludine, a yellowish liquid, must be

applied which temporarily seals the surface.

We were a bit too aggressive with the sander

when removing the paint and an extra step of

filling and fairing became necessary. After

that, three coats of high build primer were

applied by the paint shop.

when removing the paint and an extra step of

filling and fairing became necessary. After

that, three coats of high build primer were

applied by the paint shop.

Now the mast was moved into the paint

shed and work began on the boom and

spreaders. Four coats of primer were

applied by hand and went through the

sanding, filling, fairing process all over again.

shed and work began on the boom and

spreaders. Four coats of primer were

applied by hand and went through the

sanding, filling, fairing process all over again.

All painted, it cured in the paint shed for a day or

two and then was moved back to the yard (along

the old railroad tracks), out of harm's way (and

everyone else's)so David could start the

challenging process of rerigging.

two and then was moved back to the yard (along

the old railroad tracks), out of harm's way (and

everyone else's)so David could start the

challenging process of rerigging.

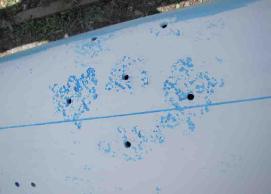

David then applied a blue wash called a

sanding guide coat.

sanding guide coat.

This product is once again sanded off, but

helps to show uneven areas which need

more filling and/or fairing.

helps to show uneven areas which need

more filling and/or fairing.

| Mast. A vertical spar, set in a ship, from which sails, or other spars carrying sails are hung. |

Bit by bit, piece by piece, parts disappeared

from the plastic bins in the saloon and

reappeared on the mast in their proper places.

Above, reassembly of the staysail furler.

from the plastic bins in the saloon and

reappeared on the mast in their proper places.

Above, reassembly of the staysail furler.

We buy water in 10-liter jugs. When empty

and slit in two, they make excellent plastic

bins for holding parts and tools.

and slit in two, they make excellent plastic

bins for holding parts and tools.

At last, after many long, hard days of

work, the re-rigging was complete.

We celebrated with an afternoon trip

to Russell for an ice cream cone.

work, the re-rigging was complete.

We celebrated with an afternoon trip

to Russell for an ice cream cone.

The area around the mast base sported

25 years of dust, grime and sludge

which needed to be cleaned out.

25 years of dust, grime and sludge

which needed to be cleaned out.

Once cleaned out and washed down with acetone,

David applied two coats of fresh white paint which

certainly made quite an improvement.

David applied two coats of fresh white paint which

certainly made quite an improvement.

During the summer season, the slipwell for the

TravelLift is busy all the time so we had to wait

for an available time slot and coordinate that with

the availability of the crane. At last, the day

came. Above, they move the mast to the slipwell.

TravelLift is busy all the time so we had to wait

for an available time slot and coordinate that with

the availability of the crane. At last, the day

came. Above, they move the mast to the slipwell.

The crane began lowering the mast...

shrouds, stays and furlers gently swaying

as they maneuvered the mast and

dropped it back into place.

shrouds, stays and furlers gently swaying

as they maneuvered the mast and

dropped it back into place.

As soon as the mast was in place, everyone

hurried to attach stays and shrouds in place to

steady it while we moved back to our berth.

hurried to attach stays and shrouds in place to

steady it while we moved back to our berth.

Rob, the rigger, clambered up the mast to

detach the crane sling and we were on our way.

detach the crane sling and we were on our way.

We were quite fortunate that it was such a

fine day with only a light breeze. Though

the current was quite strong, we had lots

of help. Mark & Brandy on "Restless"

and Kevin on "Extravagant" came over to

lend a hand. Thanks to their help and the

luck of the gods, we managed to leave

our berth, get into the slipwell, step the

mast and return to the berth with no

problems at all...all within an hour's time.

fine day with only a light breeze. Though

the current was quite strong, we had lots

of help. Mark & Brandy on "Restless"

and Kevin on "Extravagant" came over to

lend a hand. Thanks to their help and the

luck of the gods, we managed to leave

our berth, get into the slipwell, step the

mast and return to the berth with no

problems at all...all within an hour's time.

The job's not done well unless some

blood is spilled. This time it was Mark's.

blood is spilled. This time it was Mark's.

| Cups is a sailboat again! |

Illustrated Sail & Rig Tuning by Ivar

Dedekam is a good reference book for

tuning the rig. (ISBN1898660670)

Dedekam is a good reference book for

tuning the rig. (ISBN1898660670)

David wasted no time and began the

static tuning as soon as we were all

snug back in our berth.

static tuning as soon as we were all

snug back in our berth.

First things first...setting the rake of the

mast. The rake is the angle at which the

mast leans aftward.

mast. The rake is the angle at which the

mast leans aftward.

Tightening the starboard cap and

intermediate shrouds.

intermediate shrouds.

A long way up the mast...David

checks the rigging and plugs in the

wind vane.

checks the rigging and plugs in the

wind vane.

Hanging in the bosun's chair, David

re-attaches the HF radio antenna.

re-attaches the HF radio antenna.

He spent a total of 2-1/2 hours up the mast checking,

tuning and re-attaching. Above, he adjusts the angle

of the top spreader. He later attached spreader boots

to prevent chafing.

tuning and re-attaching. Above, he adjusts the angle

of the top spreader. He later attached spreader boots

to prevent chafing.

The mast boot surrounds the mast and keeps

water from dripping down the mast to the

salon below. First attempt was not successful

and it had to be done again.

water from dripping down the mast to the

salon below. First attempt was not successful

and it had to be done again.

We purchased all new line for halyards and

sheets. Each line end had to be whipped to

prevent fraying or, in the case above, spliced to

allow a shackle to be hooked on.

sheets. Each line end had to be whipped to

prevent fraying or, in the case above, spliced to

allow a shackle to be hooked on.

Once the mast was complete, the

boom needed to be re-rigged.

boom needed to be re-rigged.

Boom before...

Boom after...WOW!